We have officially opened our new Industrial AI lab! It’s been a few months in the making, with all the main components and mechanics being built by-hand, but it was well worth the time – and we’re already getting to work. In just the first couple weeks, we’ve been able to conduct remote demos, engineer a world first using voice commands to control Spot, and even figured out a way to have a conversation with robots.

But let’s back up a bit: why create an Industrial AI Lab in the first place? Particularly one that is miles away from the sites and facilities where we deploy our solutions? The lab allows operations and innovation teams the ability to rapidly explore the capabilities of our Cognitive Inspection Platform in real-time, both in-person and remotely. It also provides a dedicated space for our engineers to incubate, test, resolve issues discovered in the field, and even explore new ideas for the way robots and advanced AI can be used for automated inspection. In other words, we can test and find new solutions, and our customers can see the impact in the field.

As we continue building our platform, we need to continuously expand on models, features, integrations and new hardware that can be used in capital intensive businesses to automate their inspection processes. With the opening of our Industrial AI Lab, we can not only build on our progress, but we can now demonstrate the power of our software to both existing and potential customers.

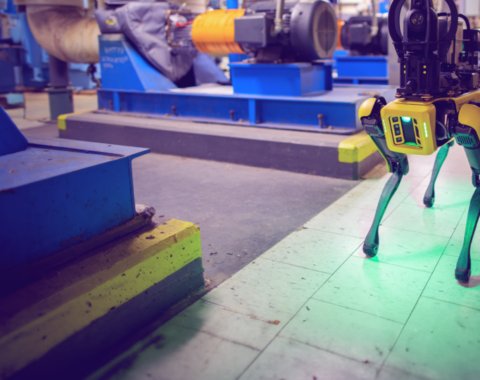

The space is efficiently packed with hardware for data collection and materials that mimic industrial situations or machine components. With a lot of our current work focused on integrations and features for Boston Dynamics’ Spot robot, we have three Spot units testing around the clock. The lab also features fixed cameras, drones, and other sensors used for data collection and analysis. In its current configuration, our “equipment boards” are testing analog gauge reading, thermal anomaly detection, facility compliance (Six Sigma “5S” boards, for example), and detecting changes in an environment, like a missing tool or fire extinguisher.

We hope that our Industrial AI lab will be a valuable asset to our team, our clients, and the industry as a whole. We look forward to using this space to push the boundaries of what’s possible with AI and robotics, and we can’t wait to see what new developments will emerge from our research and testing.

If you’re interested in learning more about our Cognitive Intelligence Platform or visiting our Industrial AI Lab, please don’t hesitate to contact us. We’d be happy to give you a tour and show you what we’re working on!